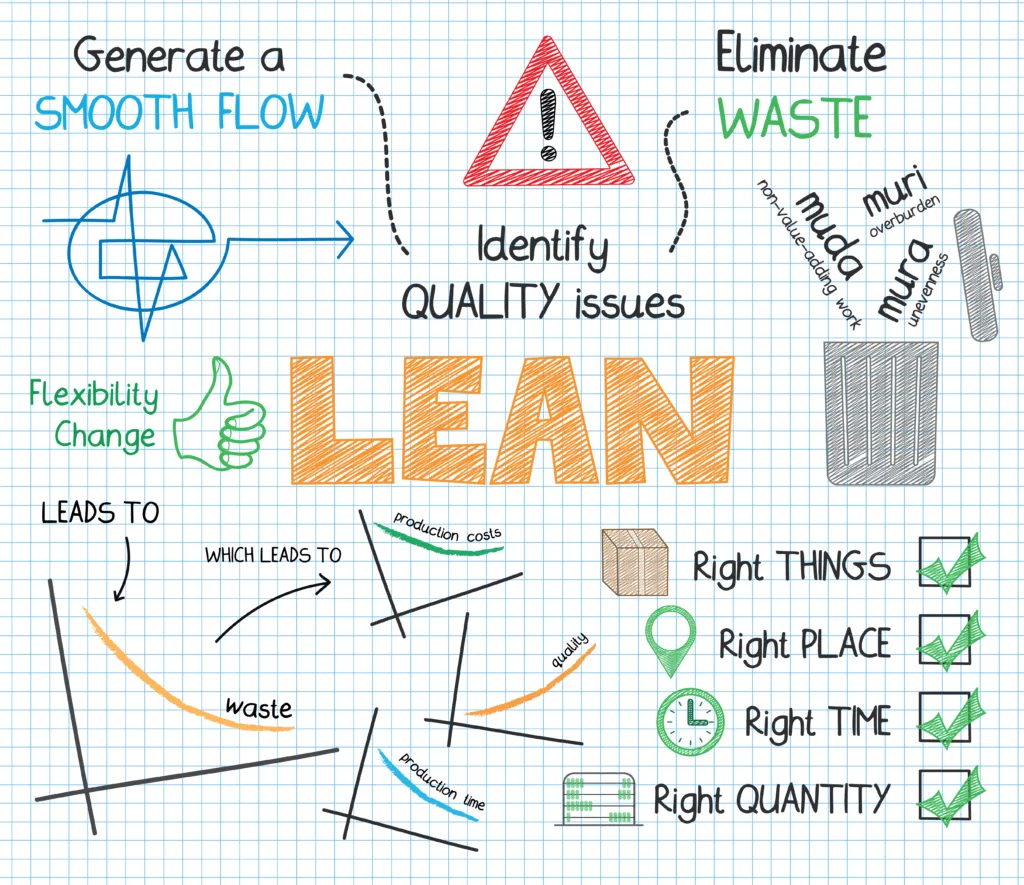

The implementation of Lean Manufacturing requires an organisation to focus its attention on improving its processes. This is done by eliminating waste, which is essentially anything that does not add value for the Customer. These improvements must then become standardised.

An organisation must follow the 5 step cycle to become lean. The flow should be continually followed with a continuous drive for the elimination of waste.

Firstly, the value of your product or service must be specified in terms of features or functionality that meet the needs of the Customer, at an agreed price and time. Value can only be truly defined by the Customer.

Secondly the value stream needs to be identified. This is the set of actions required to convert a product or service from raw material, right through to use by the Customer.

Actions in the value stream fall into three broad categories:

All but the value adding actions are waste and therefore must be eliminated.

Next, products should flow through a lean organisation at the rate that the Customer needs them, without being caught up in inventory or delayed. Therefore the process flow should only contain value adding operations. Often a re-design of processes along with a reduction in batch sizes is required to establish that smooth flow. To achieve an effective flow, cross functional team working and the use of new appropriate measures are essential.

Pull systems ensure that the Customer gets what they want, when they need it. They synchronise production and Customer demand so that only what is needed at the next stage of the process is actually being produced. The ‘pull’ needs to take place along the whole value stream (including Customers and suppliers) to gain the full benefits of a pull system.

Finally, perfection applies to all aspects of the value stream – targets, specification, documentation, costing, pricing and delivery. The organisation will become leaner and deliver higher quality products to Customers by attacking variability in all processes and controlling them.

Remember, perfection will never be achieved, as it is always possible to improve!

These Related Stories

No Comments Yet

Let us know what you think