Push and Pull Systems link manufacturing processes together to ensure production is synchronised.

Simply put, Pull systems link processes with Customer demand to ensure the right parts are produced and delivered to the right place at the right time.

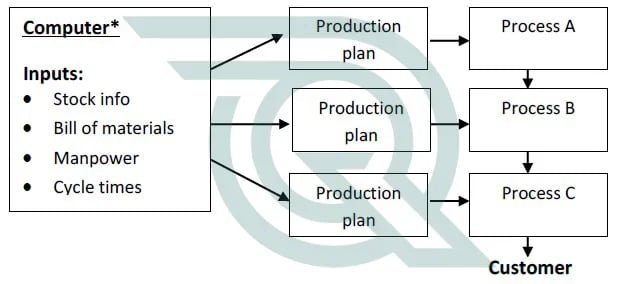

With the push system, manufactures launch material and produce goods according to a production plan. Batches of parts are produced at each stage of the process, leading to excess work-in-progress.

Vast computer systems produce the production schedules, which rely on the accuracy of base data such as quantities, locations, lead-times and scrap rates. If defects occur, stock levels are incorrect or machines break down, then the initial assumptions become invalid.

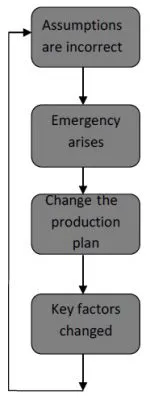

What happens?

New figures are fed into the computer to compensate for these problems, but if more changes occur, a spiral of chaos can start very quickly.

A Typical Push system:

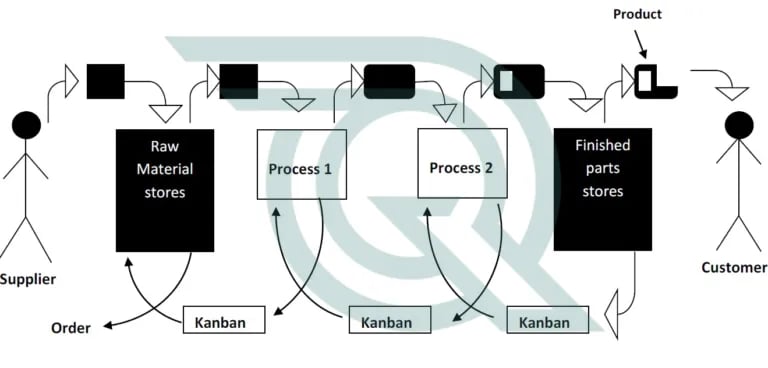

A production system can be more effectively controlled by use of the pull systems and a method called Kanban. Kanban has frequently been misunderstood. It is not the system but is the method of communicating between adjacent stages of the manufacturing process. It takes the form of cards, lights, coloured balls etc.

The pull system is basically a stock replenishment system. Customers drive the process by pulling the exact quantity of parts required out of the finished parts stores. A Kanban, which is on the container, is then passed back to the preceding process as a production instruction to make another container of these parts.

These actions are repeated upstream throughout the process. The production process is thus controlled by simple rules and Kanban, rather than computers.

These Related Stories

No Comments Yet

Let us know what you think