Most businesses have procedures, processes or other areas that need improvement. All too often, outdated workflows are left in place because no one in the company has the time, energy or expertise to enhance or adapt them. This often leads to avoidable inefficiencies, wasted resources and unnecessary expense.

Training or hiring an Improvement Technician could give businesses the drive and the resources they need to boost efficiency, improve workflows and get the results they really need.

Improvement Technicians are professionals who use Lean principles to identify inefficiencies within a business. These inefficiencies could include wasted time, wasted materials or wasted resources.

Improvement Technicians can then use their expertise to streamline workflows, reducing unnecessary steps, cutting costs and improving productivity.

Improvement Technicians collect, analyse and interpret data in order to gain valuable insights into process performance. Utilising a data-driven approach is important as it ensures businesses base their decisions on facts and measurable outcomes, rather than assumptions.

During an Improvement Technician apprenticeship, professionals are trained in Lean and Six Sigma methodologies and are taught how to apply these principles to real-world situations. They learn techniques such as Root Cause Analysis (RCA) – an effective and systematic problem-solving process - and Plan-Do-Check-Act (PDCA) – a cyclical approach to continuous improvement.

When implemented in a business setting, these techniques can have a significant and long-term impact on workflows and processes. Applied properly, they can help organisations to improve efficiency at every level.

Often, standardisation is an important step on the path to improved efficiency. By creating standard operating procedures (SOPs) and process maps, Improvement Technicians ensure consistency and repeatability within an organisation. Raising levels of consistency and repeatability helps to minimise errors and enhances operational reliability across departments.

One of the most important benefits of having an Improvement Technician in your business is that they work to engage teams in problem-solving activities. This helps to boost critical thinking skills within the organisation and encourages a proactive approach to efficiency.

Through training and coaching, Improvement Technicians empower team members to seek out and implement small, ongoing improvements. If every member of a business is continually looking for ways they can improve efficiency and enhance workflows, the organisation as a whole is likely to see real benefits.

Through smarter resource allocation, waste reduction and process optimisation, improvement technicians help businesses achieve enhanced efficiency and greater profitability. Long term, their work leads to lower operational costs, improved customer satisfaction and better levels of sustainability.

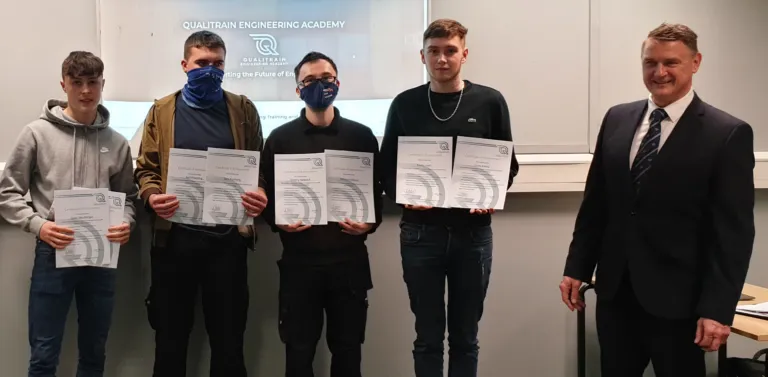

If you’re interested in an Improvement Technician level 3 apprenticeship, or would like to know more about engineering apprenticeships in general, we can help. Unlock your team's potential with Qualitrain's fully funded Level 3 Improvement Technician Apprenticeship and enhance your business performance today!

Image Source: Canva

These Related Stories

No Comments Yet

Let us know what you think