Share this

Previous story

← Apprentice Lifting Engineer Vacancy

Next story

Free Engineering Course for Unemployed →

Process mapping is a powerful tool that defines what actually happens to products and services through a complete process and highlights numerous wastes and issues within the process.

Process mapping is a method of depicting process, material or information flow in a diagrammatic form.

It is always important to collect real data when analysing a process. This is best achieved by “walking the route” which involves following a part through a process from raw material to the finished product. Whilst walking the route important data. Is gathered, such as distances travelled and operation times. Areas of waste will be seen and should be recorded, such as over-production and inventory.

It is extremely important that real data is gathered. No matter how well an area is known, a process map cannot be constructed whilst sitting in a room as assumptions will be made and areas of waste not seen. All activities in the process should be recorded, including the transportation distances, waiting times, and process times.

The activities recorded on the map as numerous wastes will be apparent. Lead times can be dramatically reduced, and time spent finding and moving parts eliminated by simple alterations to the process. In some cases, distances travelled by parts in a process can be over three miles and over 95 per cent of the time can be spent queuing.

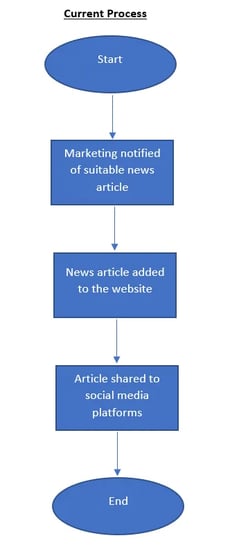

There are a few different types of process maps. The most simple version is a basic flow chart. This visually displays each step of a process without going into too much detail. An example of a basic flow chart is below:

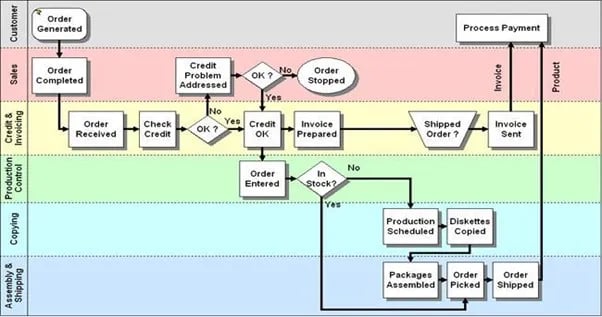

Another example of a process map is a Swimlane Process Flow. This goes into more detail than the basic flow chart above, typically adding in who the responsibility of each task lies with. For organisations, this could be a specific department or customer:

If you’re looking to really drill down into the detail, a Value Stream Map is the ideal solution to provide a wealth of knowledge and insights into your current process and where the wastes are coming from. Contact us today for help with streamlining processes within your business.Contact

These Related Stories

No Comments Yet

Let us know what you think